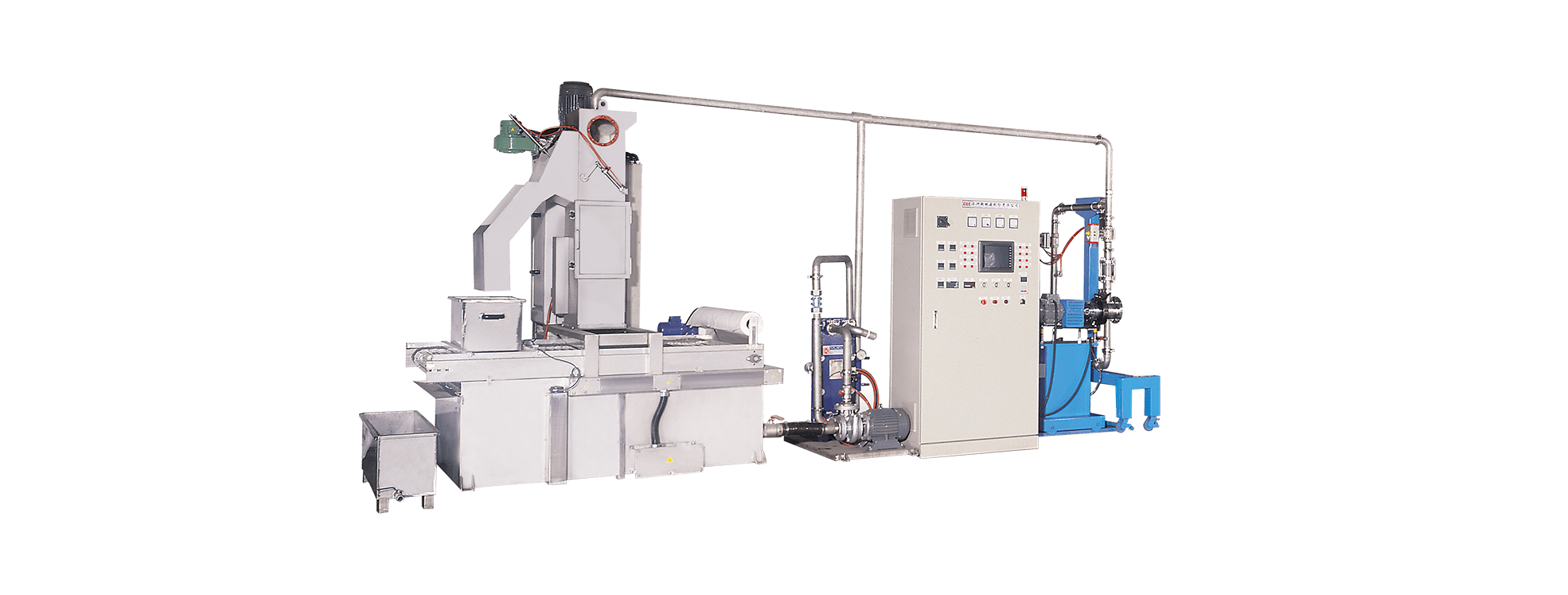

CM-UWP Under Water Pelletizer

DESCRIPTION

Advantage:

- Ease of operating.

- When unusual conditions happen, there is a signal info reminder on the HMI.

- Die face is made of tungsten steel and is wear-resistant.

- Reducing the abrasion during the manufacturing process rather than the traditional pelletizer.

-

Selectively arranged with the following equips depends on the output demand :

- Linking to the cooling water or heating water.

- Making the crystal effect.

- Linking to the automatic control system.

- Linking to the heat insulation die face and reducing the energy loss.

- Suitable materials: TPR, TPU, TPE, EVA, HDPE, LDPE, PP, SBS, SEBS, R-PET.

a. Flowing Valve:

-

Features:

1. To supervise the molten state of plastic granules.

2. When equipment shuts down abnormally, it would be turned into the divert mode, to avoid destruction of the equipment.

- Included with one set of die for material output.

- Included with heater bar.

- Included with oil pressure displace unit.

b. Die Lip Temperature Control System:

- Included with temperature control system for die lip.

c. Cutting Machine:

- Material of Cutting Chamber is SUS304 Stainless Steel.

- Servomotor controls the pressure between cutting knives and die lip.

- Clip of mold and cutting chamber can be assembling.

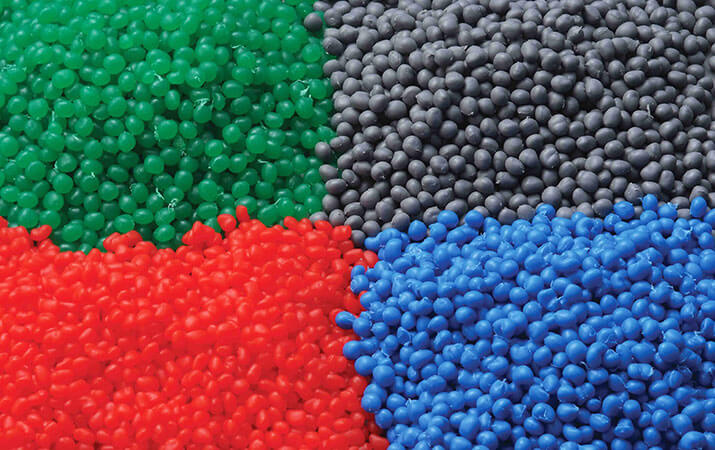

APPLICATIONs

CONTACT

If you have any needs, or are interested in our products, welcome to contact us.

Read More